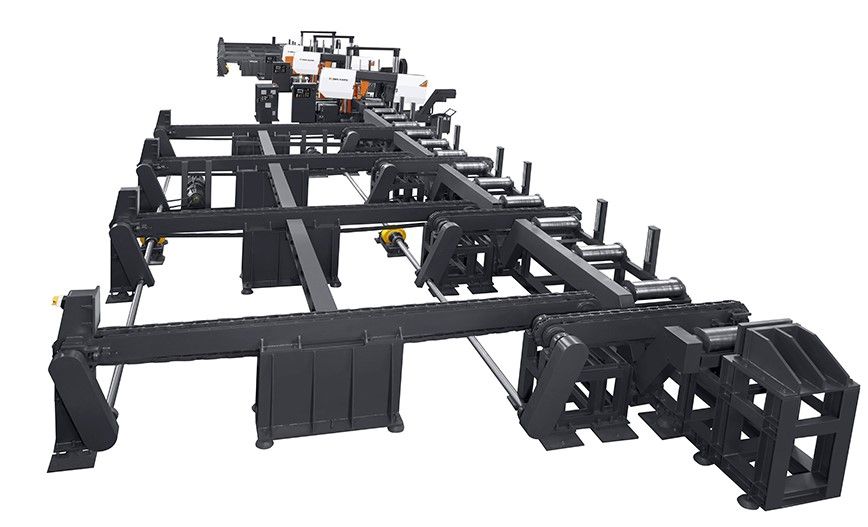

Steel Plant Production Line with Three Saws Simultaneously Cutting

Customized to cut the heads, ends and at designated midpoints of bundled profiles up to 12.5M long

At a steel plant, profiles (e.g. angles, channels, beams and etc.) made often exceed 20M in length. In consideration of transportation costs involved, they need to be trimmed and cut to length onsite.

In response to such need coming from our steel plant customer, Cosen customized an automation production line called H3 with three bandsaw simultaneously cutting along a roller track, one infeed traversing table and one outfeeding table. The three bandsaw respectively perform cuts at the head, end and midpoint of designated lengths. Infeeding, cutting, outfeeding forms one cycle and continues on until out of material or outfeed table is full. H3 has realized our customer’s dream of automatic unmanned production and helped accelerate processing time of these profiles exponentially.

Do you have any need for an automatic production line like this? Feel free to contact Cosen today to share your dream idea and a quote. We are happy to help!