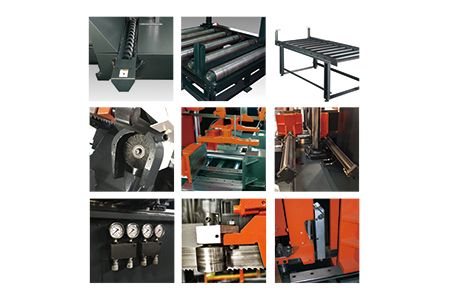

Bandsaw Machine Accessories

Standard and optional accessories you need on Cosen’s bandsaw

As your material may come in different sorts and shapes, Cosen provides a variety of accessories with our bandsaw to enable clamping, cutting and chip removal best for your specific material.

Our list of a bandsaw machine accessories includes: top clamps, prism vises, pressure regulators, mist spray systems, chip conveyors, vibration dampers, blade deviation detectors, anti-wedging devices, blade height decoders, powered roller tables, safety packages and etc. Please consult Cosen what works best for your cutting experiences.

Bandsaw Machine Hydraulic Top Clamp

Required for bundle cut applications, the Bandsaw Machine top clamps are hydraulically powered to provide secure clamping and works with the single/bundle...

Bandsaw Outfeed Traversing Table

Removing cutoff pieces and clearing the cutting zone "in time" is crucial to achieving real automation especially when cutting long beams, angles and pipes....

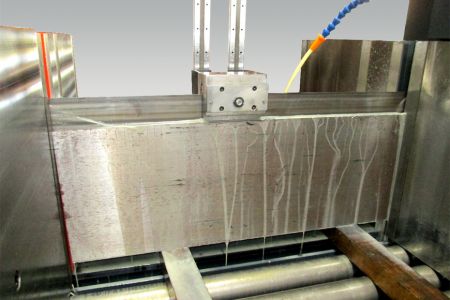

Bandsaw Machine Hydraulic Chip Conveyor

Hydraulic Chip Conveyor for Bandsaw Machine is effective and convenient, the shaftless design incorporated allows for maximum chip removal. Also, this...

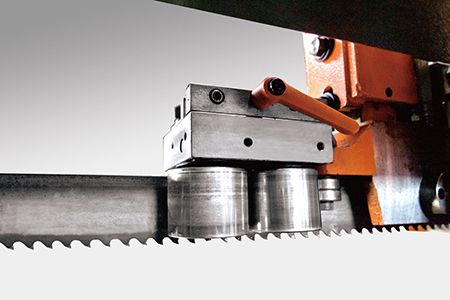

Bandsaw Machine Vibration Damper

Cosen's vibration damper for bandsaw machine can effectively reduce blade vibration produced under high-speed cutting. Especially for cutting small materials...

Bandsaw Machine Blade Deviation Detector

With the blade deviation detector, the bandsaw machine will stop automatically once the blade deviates beyond preset range, preventing unnecessary loss...

Bandsaw Machine Blade Height Decoder

Through advanced encoder technology, the bandsaw machine displays the exact height position of the saw frame. This allows a linear downfeed rate to be calculated...

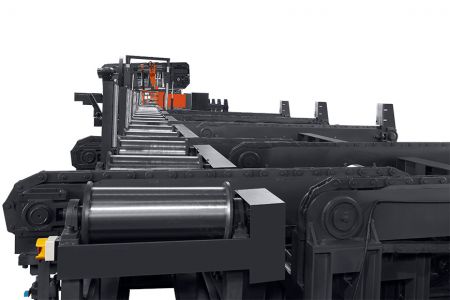

Bandsaw Machine Roller Table

Used when cutting long work pieces, the sturdily-built roller table keeps material level with the bandsaw machine. Side rollers equipped on the roller...

Bandsaw Machine Powered Roller Table

Used when cutting long work pieces, the sturdily-built roller table keeps material level with the bandsaw machine. Side rollers equipped on the roller...

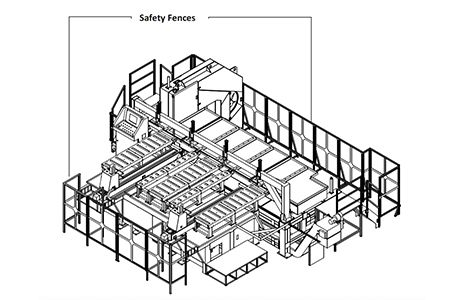

Bandsaw Machine Safety Fence

Occupational safety and health (OSH) for bandsaw machine has become a global concern and inevitable responsibility at the factory management / floor supervisors....

Bandsaw Machine Remote Control

Applicable to all saws in essence, the remote control comes in handy when placing and removing material from the saw. With functions to control movements...

Vertical Plate Saw Hydraulic Blade Change Device

Applicable to large plate saws, the hydraulic blade change device features in multiple solid hydraulic cylinders, which take turns to hold the work table...

Bandsaw Machine Middle Vibration Dampener

While cutting wide structural materials i.e. H-beam or wide blocks/plates on a large capacity horizontal bandsaw, the distance between the two guide seats...