Industry 4.0 Plug-and-playable for Bandsaw Machines

Manage key machine data and diagnose blade health anytime and anywhere with Cloud Predictive Computing (CPC) presented by Cosen and MechaLogix.

Feature Overview:

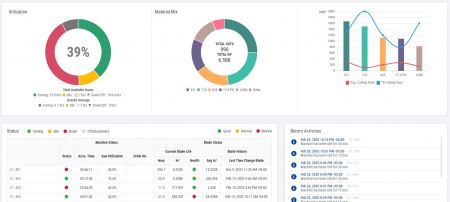

Dashboard Overview

• Gain a complete picture of your operations at a glance.

• Monitor utilization trends with flexible daily, weekly, and yearly views

• View current shift status and material being processed today

• Analyze performance by material type with dynamic rate charts

• Track production across machines, work orders, blade health, and event triggers

• Group and manage machines with factory-level customization

• Access in-depth machine condition insights and blade diagnostics

• View detailed cutting parameters in real time

TV Display Mode

• Turn your factory floor into a live dashboard.

• Real-time display of machine status: Utilization %, Downtime, Idle, Cutting, and Power-Off

• Manual group control for machine management

Shift Management

• Streamline productivity tracking across shifts.

• Configure shift settings via web or directly on the HMI

• Automatically generate shift-based reports

• Choose work order or machine-based performance metrics for each shift

Automatic Reports

• Get critical insights delivered straight to your inbox.

• Schedule reports daily, weekly, or monthly

• Select delivery time, date, and shift

• Receive completed order summaries including materials, processing time, and energy usage

• Access blade usage and machine utilization reports with shift-level granularity

📌 Mobile App Integration

• Stay connected from anywhere.

• Real-time machine data at your fingertips

• Instantly switch between customer accounts

• View work order progress and full machine status

• Evaluate blade health and power statistics

• Browse machine data by day, month, or year

Open API Connectivity

• Built for integration and scalability.

• RESTful API architecture with JSON format

• Secure access via OAuth 2.0 authentication

• Seamlessly connects with ERP, MES, mobile apps, websites, and IoT platforms

Permission Management

• Control access with precision.

• Define roles and permissions for users and departments

• Customize views by country or plant

• Full visibility of backend configuration settings

Q-Cut: Smart Barcode System

• Simplify data input and tracking.

• Instantly generate custom QR codes and barcodes

• Online barcode generator for fast deployment

• Include order details: dimensions (W x H x L), material type, material drawing, and cutting specs

Alarm Notifications

• Stay ahead of problems with intelligent alerts.

• Define who gets notified and how often

• Set alert scopes for critical issues

• Customize email formats for clear communication

Event Log & Notification History

• Never miss an important event.

• Search and review all trigger details

• Track complete notification delivery records

Choose whom to receive automatic reports so important messages are not missed or for troubleshooting. Format and timing of the automatic reports can be easily configured based on your management preferences. All cutting records are filed nicely and can be looked up for reviews.

CPC can be installed on any type of machines, directly takes your pain away in machine communication and integration and empowers you with data visibility. With CPC, you get to learn more about your plant and turn it into a SMART FACTORY.

Make Tool Life Foreseeable, Machine Visible with Cosen CPC (Cloud Predictive Computing) System

CPC (Cloud, Predictive, Computing) machine healthy diagnosis system presented by Cosen and Mechalogix can be easily installed across different types of machines....

AI Cutting: Autonomous Sensing, Computing and Calibrating

Machine ages. Blade dulls. Material may have variances. “Better” yet, machines and blades are very different from brand to brand. And then your operators...

Sensor Mounting Bracket Installation

Our carefully designed sensor mounting brackets can adapt to different brands of sensors and can be mounted onto different machine parts, regardless of size...

Automatic Cutting Report &Analysis

CPC Connect, Cosen’s patented cutting analytic tool, provides automatic cutting report and analysis to help you first understand how machines and blades...

Connecting Bandsaw Machine to ERP

Through various communication methods, you can connect bandsaw machines to your company's ERP. By integrating your company's ERP system with the Internet...

Connecting Bandsaw Machine to APP

Cosen provides internet-connectable machines and devices to make factory-to-internet communication happen. Sawlogix app is available for both Android and iPhone...

Scanning & Data Input to Bandsaw Machine

Cosen’s bandsaw machine can come with an optional scanner, which replaces manual data input with direct QR code or bar code scanning. Data input can contain...

Showing Bandsaw Machine Status on a TV Dashboard

Cosen’s bandsaw machine connectivity service includes TV Dashboard, which allows you to customize and display important machine and production status...

Bridging Bandsaw Machine via Open API

Cosen’s cloud services offers open API for our customers to easily collect key production information and bridge it to their own system.

Creating Your Own AI Cutting

Cosen’s AI CUTTING is enabled by the use of intelligent vibration sensors, which collect cutting parameters and vibration specific to the machine. A unique...

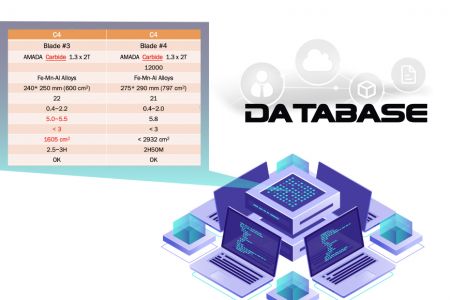

Establish exclusive Data Base/machine operation speed

osen help you establish your own exclusive material library with cutting parameters built inside. Information required for cutting such as material name,...