Honeycomb and FRP Cutting

Honeycomb and fiberglass (FRP) straight / angle cutting bandsaw made for aircraft building

With many experiences selling to our aerospace industry customers and customization abilities accumulated over the years, Cosen is honored to have had the opportunity to participate in building honeycomb and fiberglass (FRP) cutting machine for two aircraft building customers, one domestically and one overseas.

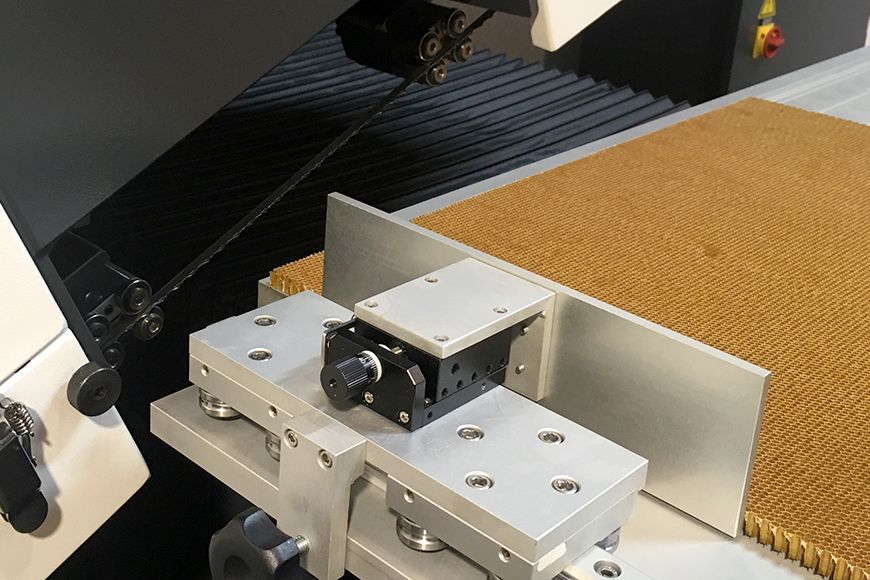

Honeycomb panel, being light, high-strength, and resistant to wind pressure, is commonly used as the core material of aircraft structures. Our domestic customer needs to cut honeycomb panels to specific width and side angles. To their request, Cosen designed a vertical plate saw with mitering sawhead, traversing workbed and special blade running at super high-speed. Honeycomb panels are cut smoothly and come out straight and as importantly, undamaged. Compared with ultrasonic sawing, our customer successfully achieved both accuracy and cost reduction on their new saw from Cosen.

In the second case of aircraft building, our customer cuts fiberglass (FRP) for aircraft cabin panel fitting with the same need for angle cutting. Glass fiber, also known as fiber-reinforced plastics, has high toughness, fire resistance, and lightweight. It produces a large amount of dust during the cutting process, so it is no surprise that dust collection is a vital design element. Cosen made a vertical plate saw with a movable, double-side tiltable workbed for straight and bevel cutting. Cutting is super-fast with the blade running up to 4570M/min.

For more machine features, please refer to Cosen's semi-automatic vertical band sawing machines SVT-3075DM and SVT-2060M.

Honeycomb and FRP Cutting | Custom Mechatronic Solutions for Enhanced Industrial Automation

Cosen Mechatronic, based in Hsinchu, Taiwan since 1976, is a top manufacturer of high-quality Honeycomb and FRP Cutting and CNC bandsaws. Specializing in innovative and precise solutions for automotive, aerospace, and construction industries, Cosen ensures reliability and efficiency in all its products. Committed to superior performance and comprehensive customer support, Cosen Mechatronic enhances productivity and operational efficiency globally.

Cosen was rated as the No. 1 Sawing Equipment Brand by U.S. Metal Center News in 2015, 2022, 2023 and 2024. In 2016, the company launched the world's first Industry 4.0 Sawing Performance & Health Prognosis App - positioning itself as the technology leader in band saw manufacturing. Cosen manufactures a variety of bandsaw designed for cutting metal materials, distributing its products worldwide. With extensive experience and expertise in bandsaw manufacturing, we provide a diverse range of cutting capabilities tailored to meet the demands of industries including construction, automotive, transportation, wind power generation, and beyond.

Cosen has been providing customers with automated assembly line solutions since 1976, utilizing advanced technology and 55 years of experience to ensure each customer's demands are met.