Bandsaw Cutting and Automation

Bridging different machines, hardware and software to automate cutting and machining process

In addition to the bandsaw machine itself, a production line involves material handling, physical movements, storages, identifications, communications, how to minimize manual work and eliminate human errors and etc.

A streamlined production line is particularly important to production efficiency particularly when dealing with large material. So not only cutting, but the material handlings before and after cutting need to carefully designed and automated to bring out best production results. With our 50 years of experience and in-house mechanical and electrical engineering capabilities, Cosen can help you automate and make your production processes more efficient and intelligent.

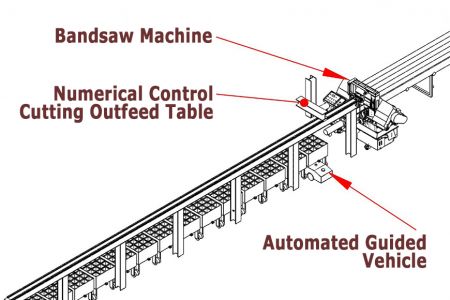

Moving Finished Bandsaw Via Self-Driving Car

After sawing is completed, the cutoff pieces need to go to their respectively designated locations. Oftentimes we need to employ some labor to pick, sort...

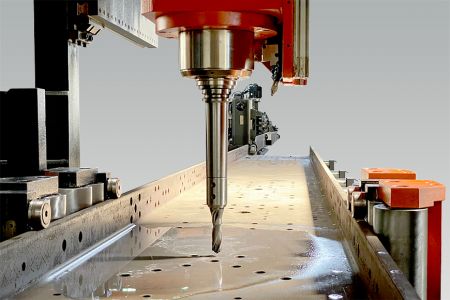

Bandsaw Collaborating with CNC Machining Center

Cosen’s bandsaw machines can connect, communicate and collaborate with CNC machines and turn your idea of automatic production line and lights-out factory...

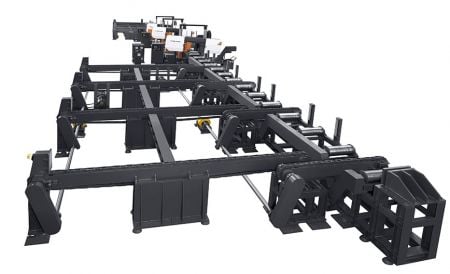

Steel Plant Production Line with Three Saws Simultaneously Cutting

At a steel plant, profiles (e.g. angles, channels, beams and etc.) made often exceed 20M in length. In consideration of transportation costs involved,...

Bandsaw Connecting to Robotic Arm

Traditionally, an outfeed roller table or discharge table is used to guide and store cutoff pieces. It, however, still requires operator intervention to sort...

Bandsaw Collaborating with Drilling Machine

As drilling and miter cutting are required on beams, structural steels and aluminum profiles almost all the time, the best way to optimize production efficiency...

Bandsaw Connecting with Automatic Storage System

With our bandsaw machine, Cosen offers automatic magazine infeed system, which allows storage of multiple workpieces and communication with your storage...

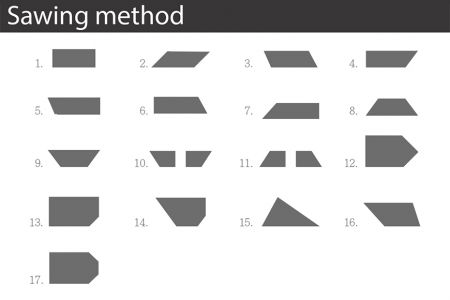

Bandsaw Cutting to Irregular Polygons

Cosen’s automatic double-mitering servo-feeding bandsaw machines provide a very intuitive user interface. 17 built-in polygon shapes are available for you to choose....

Bandsaw Integrated with Automatic Sorting System

Cosen’s bandsaw machines can be equipped with our automatic sorting system. Cut pieces are sorted (divided) according to each individual identity e.g....

Bandsaw Integrated with Infeed/Outfeed Transfer Conveyor System

Cosen’s transfer conveyor system works with infeed and outfeed mechanism (often powered roller table), allowing users to load multiple pieces of material...