500mm x 550mm Capacity Bandsaw Machine with Customized Cutting System

H3-5050

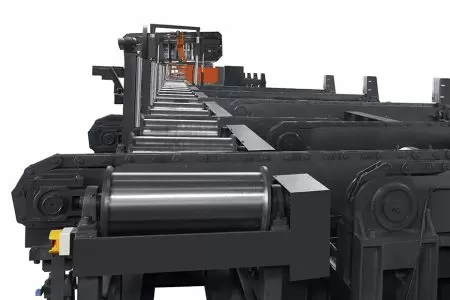

Bandsaw Machine with Fully Automatic Cutting System, Completed Cutting Line

Redefining Productivity for 500 × 550 mm Cutting Capacity

The H3-5050 is engineered for facilities that process large quantities of structural steel every day.

The concept is that a single-head saws could no longer keep up with the production demand, and manpower scheduling became increasingly difficult.

The goal is to triple the output without tripling manpower or floor space.

Rather than simply cutting faster, the H3-5050 is to use less operators to do less while the machine cuts more.

Design Built From Real Operator Experience

Operators often describe their first run on the H3-5050 as:

“Feed in, position, cut—everything flows without interruption.”

This smooth workflow comes from several key designs:

● Triple-Head Synchronous Cutting

All three saw heads follow a shared reference point, descending simultaneously without interference.

This gives the operator three precise cuts in a single cycle, eliminating repeated feeding.

● Custom Material Rack Integration

The system is frequently paired with custom-built infeed and outfeed racks, reducing or even eliminating the need for manual handling.

From customer shared:

"We used to have three people working at the line. Now one operator monitors the HMI and the batch runs by itself."

● Large 10” Touch-Screen HMI

Operators can easily monitor blade condition, cutting parameters, feeding status, and error messages.

Even new users become comfortable within minutes.

Built for Structural Steel, H-Beams, and High-Volume Production

The H3-5050 specialized in:

H-beams, I-beams, large tubes, square columns

Batch cutting into up to three equal lengths per cycle

Facilities aiming to reduce labor while increasing consistency

Production lines with roller tables or automated material-handling systems

In a real deployment at a major Thai steel-fabrication plant, the H3-5050 delivered:

30–45% increase in daily throughput

Reduction of two operators per shift

20% smaller material-handling footprint

These improvements were verified directly on-site.

Why Choose the Cosen H3-5050?

Over 50 years of sawing engineering and manufacturing expertise

Global service support and reliable spare-parts supply

Customizable material-handling systems

Industrial-grade construction designed for long-term durability

The H3-5050 is more than a machine—it is a complete cutting solution for high-volume steel processing.

The H3-5050 is produced for high-volume steel processing and continuous cutting operations, especially in large-heavy production environments. A customized machine was implemented at a major construction material supplier in Thailand, with a customized material rack system integrated throughout the factory.

With three synchronized bandsaw machines operating simultaneously, one operator can control all the production line which increase efficiency compare to traditional single band saw machine. The automated production line enable smooth material loading and unloading, and reducing labor cost and improving operational efficiency.

Operators report a streamlined workflow—from selecting pre-set cutting parameters via the touch panel to automated feeding and cutting.

COSEN’s 50 years of experience in metal cutting, the H3-5050 showcases our commitment to precision, efficiency, and industrial integration. It is designed specifically for large-scale structural steel processing and construction material production.

Key features include:

Triple synchronized saw heads for parallel cutting of three pieces simultaneously

Cutting capacity of 500 × 550 mm, suitable for large H-beams, square pipes, and channel steel

Touchscreen operation and automation, with 100 memory settings for quick changeovers

Servo-controlled feeding and automatic blade tension, reducing wear and improving blade lifespan

Full integration with external systems, including material racks, conveyors, and plant-wide logistics solutions

The H3-5050 is one of COSEN’s successful models for customized large-scale applications, with the first unit delivered to a leading building materials group in Thailand. The system has received strong endorsements from operators and plant managers for its throughput, stability, and integration capabilities.

Proven international deployment across worldwide

Showcased at major global machine tool exhibitions, including EMO, TIMTOS, and IMTS

Recognized technical leadership in high-capacity sawing and smart automation integration

COSEN is not only manufactures high-performance saws but also delivers comprehensive service and support, ensuring long-term customer trust and reliability.

Robust structural build tested for continuous operations

Custom material rack design service available for different needs

On-site installation, training, and preventive maintenance guidance

Spare parts availability and global service network, with quick-responses in Taiwan and US

The H3-5050 is more than just a high-capacity saw — it's a complete heavy-duty cutting solution for production lines of factory.

Standard Features

- Customized cutting system satisfied user requirement.

- H3-5050 cutting capacity.

- 500mm H x 550mm W.

- H-beam, I- beam- tube, channel.

- 10hp saw motor.

- 2hp hydraulic system.

- 1/8 hp coolant pump.

- Blade width : 54mm.

- 10" HMI Touch Screen & Mitsubishi PLC Controller.

- 100 individual jobs can be programmed and stored.

- Automatic kerf compensation.

- "Save-a-Blade" function.

- Rapid troubleshooting via error feedback system.

- Scrape-free vise plates.

- Full stroke hydraulic cylinder.

- Inverter-controlled infinitely variable blade speed.

- Automatic hydraulic blade tension device.

- Hydraulic Chip Conveyor.

- Vibration Damper.

- Blade Height Decoder.

Specification

| Model | H3-5050 | ||||

|---|---|---|---|---|---|

| Name | Central Controlled Triple Head Profile Cutting Bandsaw System | ||||

| Capacity Max. | |||||

| Round | 520 mm (20.4 in.) | ||||

| Square | 500 mm (19.6 in.) | ||||

| Rectangular (H x W) | 500 x 500 mm (19.6 x 19.6 in.) | ||||

| Bundle Cutting | Front Top Clamp | W: 0 - 575 mm (0 - 22.6 in.) H: 0 - 550 mm (0 - 21.6 in.) | |||

| Rear Top Clamp | |||||

| Saw Blade | Speed | 27 - 141 m/min (89 - 462 fpm) | |||

| Dimension (L x W x T) | 6,600 x 54 x 1.6 mm (260 x 2 x 0.063 in.) | ||||

| Tension | Hydraulic with automatic blade breakage detection 2400 - 2600kg / cm² (Tolerance: +100 - +150 kg / cm²) | ||||

| Guide | Interchangeable tungsten carbide | ||||

| Cleaning | Steel wire brush | ||||

| Electricity Output | Saw Blade Motor | 10 HP (7.5 kW) | |||

| Hydraulic Pump | 2 HP (1.5 kW) / 3 HP (2.2 kW) | ||||

| Coolant Pump | 1/4 HP (0.18 kW) / 1 HP (0.75 kW) | ||||

| Fluid Tank UNIT: L | Hydraulic Fluid | 90 L (23.7 gal) | |||

| Coolant Fluid | 1040 L (274.7 gal) | ||||

| Vise Clamping | Control Method | Hydraulic with full stroke cylinder | |||

| Minimum Clamping Capacity | 0 mm | ||||

| Remnant Length | ------------------------- | ||||

| Feeding | Single Stroke | ------------------------- | |||

| Multiple Stroke | 99 M or 999 in. | ||||

| Workbed | Height | 1212 mm ( 47.7 in.) | |||

| Weight Capacity | ------------------------- | ||||

| Weight | Net Weight | ------------------------- | |||

| Gross Weight | 56,320 kg (124,164 lb) | ||||

| Floor Space | (L x W x H) | 40,000 x 8,200 x 2,950 mm (1574 x 322 x 116 in.) | |||

* Design and specifications are subject to change without notice & obligation.

* Machines may be shown with some options.

Type of Saw

- Horizontal

Automation

- Automatic

Miter

- NO

Automation Type

- SNC

Production Line

- Horizontal-Column

Capacity-Max. Height (mm)

- ≦500

Capacity-Max. Width/Throat (mm)

- ≦500

Capacity-Round (mm)

- 520

Top Clamp-Min.~Max. Height (mm)

- 0~550

Blade / Circular Saw Width (mm)

- 54

Blade Speed Min.~Max. (M/min)

- 27~141

- Video

- Download

500mm x 550mm Capacity Bandsaw Machine with Customized Cutting System | High-Precision Automation Equipment for Efficient Manufacturing

Cosen Mechatronic, based in Hsinchu, Taiwan since 1976, is a top manufacturer of high-quality 500mm x 550mm Capacity Bandsaw Machine with Customized Cutting System and CNC bandsaws. Specializing in innovative and precise solutions for automotive, aerospace, and construction industries, Cosen ensures reliability and efficiency in all its products. Committed to superior performance and comprehensive customer support, Cosen Mechatronic enhances productivity and operational efficiency globally.

Cosen was rated as the No. 1 Sawing Equipment Brand by U.S. Metal Center News in 2015, 2022, 2023 and 2024. In 2016, the company launched the world's first Industry 4.0 Sawing Performance & Health Prognosis App - positioning itself as the technology leader in band saw manufacturing. Cosen manufactures a variety of bandsaw designed for cutting metal materials, distributing its products worldwide. With extensive experience and expertise in bandsaw manufacturing, we provide a diverse range of cutting capabilities tailored to meet the demands of industries including construction, automotive, transportation, wind power generation, and beyond.

Cosen has been providing customers with automated assembly line solutions since 1976, utilizing advanced technology and 55 years of experience to ensure each customer's demands are met.