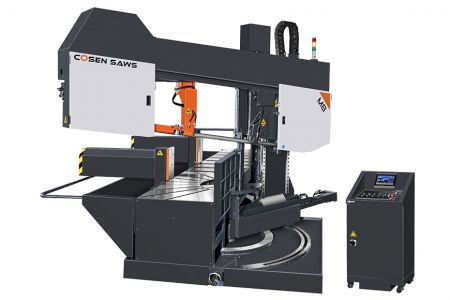

800mm x 500mm Double Miter, 30 Degree to 150 Degree Angle Cutting Machine for Structural Material

M8

Two ways swivel, Angle cutting band saw for cutting Structural material

SMART MACHINE CLOUD SERVICE CONNECTABLE

M8 bandsaw machine has a capacity of 500mm for round materials and a width of 800mm. It features a large-angle swivel, ranging from 30 degrees to 150 degrees, which allows the machine to make cuts at various angles. The machine's 2000mm stroke helps to save feeding time. It is designed for cutting structural materials, such as H beams, I beams, pipes, and channels. Equipped with Smart Numerical Control, the M8 model is user-friendly and ideal for mass production.

The Smart Numerical Control technology can be programmed for up to 100 different jobs, including the quantity and length of each cut, with features like Automatic Multiple Indexing and Automatic Kerf Compensation. Cutting information, such as blade speed, down feed speed, cutting rate, blade life, and error messages, is clearly displayed for ease of use.

This bandsaw is designed for cutting structural materials such as H beams, I beams, and pipes, with a width of up to 800mm. It features angle cutting capabilities ranging from 30 degrees to 150 degrees. The machine is equipped with an automatic programming function, which facilitates easy mass production. Additionally, it boasts a 2000mm stroke that can be completed in just 12 seconds, significantly saving feeding time.

Standard Features

- 10" HMI Touch Screen & Mitsubishi PLC Controller.

- 100 individual jobs can be programmed and stored.

- Automatic kerf compensation.

- "Save-a-Blade" function.

- Rapid troubleshooting via error feedback system.

- Scrape-free vise plates.

- Full stroke hydraulic cylinder.

- Inverter-controlled infinitely variable blade speed.

- Automatic hydraulic blade tension device.

- Hydraulic Chip Conveyor.

- Vibration Damper.

- Blade Height Decoder.

Optional Accessories

- Hydraulic Top Clamp

- Vise Pressure Regulator

- Blade Deviation Detector

- 2M Heavy Duty Roller Table

- 3M powered roller table

- Mist coolant system

- CPC Connect

Specification

| Model | M8 | ||||||

|---|---|---|---|---|---|---|---|

| Name | Double Miter Programmable Automatic Horizontal Bandsaw | ||||||

| Capacity Max. | (Miter) Angle | 0° | +45° | -45° | +60° | -60° | |

| Round | 500 mm (19.6 in.) | 480 mm (18.8 in.) | 480 mm (18.8 in.) | 320 mm (12.5 in.) | 320 mm (12.5 in.) | ||

| Square | 500 mm (19.6 in.) | 480 mm (18.8 in.) | 480 mm (18.8 in.) | 320 mm (12.5 in.) | 320 mm (12.5 in.) | ||

| Rectangular (H x W) | 500 x 800 mm (19.6 x 31.4 in.) | 500 x 480 mm (19.6 x 18.8 in.) | 500 x 480 mm (19.6 x 18.8 in.) | 500 x 320 mm (19.6 x 12.5 in.) | 500 x 320 mm (19.6 x 12.5 in.) | ||

| Bundle Cutting | Front / Rear Top Clamp | 500 x 800 mm (19.6 x 31.4 in.) | 500 x 480 mm (19.6 x 18.8 in.) | 500 x 480 mm (19.6 x 18.8 in.) | 500 x 320 mm (19.6 x 12.5 in.) | 500 x 320 mm (19.6 x 12.5 in.) | |

| Saw Blade | Speed | 20 - 100 m/min (66 - 328 ft/min) | |||||

| Dimension (L x W x T) | 7,620 x 54 x 1.6 mm (300.0 x 2 x 0.063 in.) | ||||||

| Tension | Hydraulic with automatic blade breakage detection 2400 - 2600kg / cm² (Tolerance: +100 - +150 kg / cm²) | ||||||

| Guide | Interchangeable tungsten carbide | ||||||

| Cleaning | Steel wire brush | ||||||

| Electricity Output | Saw Blade Motor | 10 HP (7.5 kW) | |||||

| Hydraulic Pump | 3 HP (2.2 kW) | ||||||

| Coolant Pump | 1/2 HP (0.37 kW) | ||||||

| Fluid Tank UNIT: L | Hydraulic Fluid | 85 L (22.4 gal) | |||||

| Coolant Fluid | 200 L (52.8 gal) | ||||||

| Vise Clamping | Control Method | Hydraulic | |||||

| Minimum Clamping Capacity | 30 mm (1.1 in.) | ||||||

| Remnant Length | 400 mm (15.7 in.) | ||||||

| Feeding | Single Stroke | 2000 mm (78.7 in.) | |||||

| Multiple Stroke | 99 M or 999 in. | ||||||

| Workbed | Height | 855 mm (33.6 in.) | |||||

| Weight Capacity | 3.1T | ||||||

| Weight | Net Weight | 6,048 kg (13,333 lb) | |||||

| Gross Weight | 6,088 Kg (13,421 lb) | ||||||

| Floor Plan (L x W x H) | 4,731 x 3,750 x 2,981 mm (186 x 147 x 117 in.) | ||||||

| 5,056 x 4,965 x 2,981 mm (199 x 195 x 117 in.) (with fence) | |||||||

* Design and specifications are subject to change without notice & obligation.

* Machines may be shown with some options.

Type of Saw

- Horizontal

Automation

- Automatic

Miter

- Double Miter

Automation Type

- SNC

Production Line

- Horizontal-Mitering

Capacity-Max. Height (mm)

- ≦500

Capacity-Max. Width/Throat (mm)

- ≦800

Capacity-Round (mm)

- 500

Top Clamp-Min.~Max. Height (mm)

- ≦500

Blade / Circular Saw Width (mm)

- 54

Blade Speed Min.~Max. (M/min)

- 20~100

Angle of swivel Min.~Max. (゚)

- 0~60

- Download

- Related Products

310mm x 500mm Double Miter, 30 Degree to 150 Degree Angle Cutting Machine for Structural Material

M5

SMART MACHINE CLOUD SERVICE CONNECTABLE M5 band saw machine can handle a 310mm round and a 500mm width. It features a large-angle swivel, ranging from 30 degrees to 150 degrees, allowing the machine to cut at various...

Details- Related Solution

Make Tool Life Foreseeable, Machine Visible with Cosen CPC (Cloud Predictive Computing) System

CPC (Cloud, Predictive, Computing) machine healthy diagnosis system presented by Cosen and Mechalogix can be easily installed across different types of machines....

800mm x 500mm Double Miter, 30 Degree to 150 Degree Angle Cutting Machine for Structural Material | High-Precision Automation Equipment for Efficient Manufacturing

Cosen Mechatronic, based in Hsinchu, Taiwan since 1976, is a top manufacturer of high-quality 800mm x 500mm Double Miter, 30 Degree to 150 Degree Angle Cutting Machine for Structural Material and CNC bandsaws. Specializing in innovative and precise solutions for automotive, aerospace, and construction industries, Cosen ensures reliability and efficiency in all its products. Committed to superior performance and comprehensive customer support, Cosen Mechatronic enhances productivity and operational efficiency globally.

Cosen was rated as the No. 1 Sawing Equipment Brand by U.S. Metal Center News in 2015, 2022, 2023 and 2024. In 2016, the company launched the world's first Industry 4.0 Sawing Performance & Health Prognosis App - positioning itself as the technology leader in band saw manufacturing. Cosen manufactures a variety of bandsaw designed for cutting metal materials, distributing its products worldwide. With extensive experience and expertise in bandsaw manufacturing, we provide a diverse range of cutting capabilities tailored to meet the demands of industries including construction, automotive, transportation, wind power generation, and beyond.

Cosen has been providing customers with automated assembly line solutions since 1976, utilizing advanced technology and 55 years of experience to ensure each customer's demands are met.